Photo: Scott Wallace / World Bank

Raian Divanbeigi, Yiruo Li, Jiang Ru, Suiko Yoshijima

Bricks help build Bangladesh’s growing economy, employing about 1.2 million workers and providing essential livelihoods to vulnerable populations such as the illiterate, poor, and migrants. But the sector also contributes to rising air pollution due to the traditional and outdated technology predominating in Bangladeshi kilns. Pollution remains a critical challenge in Bangladesh – it was ranked 177th among all 180 countries in the 2022 Environmental Performance Index.

Compounding these environmental issues, Bangladesh’s brick production provides low-quality jobs with serious occupational health and safety risks. The Bangladesh Environmental Sustainability and Transformation Project (BEST) and Supporting Effective Jobs Lending at Scale (SEJLS) are modernizing the Bangladeshi brick sector to benefit people and the planet. Approved in December 2022, the BEST project aims to strengthen the government’s environmental management and to pilot new financing mechanisms to promote green investments in brick production and other industries. Integrating the jobs angle into the project’s environmental transformation agenda, SEJLS supported BEST to identify and address interlinked jobs challenges in the brick sector.

Dirty jobs, vulnerable workers

According to SEJLS-financed job studies, job vulnerability is widespread among workers in this sector. Most brick kilns in the country are operated seasonally only for 4-5 months, resulting in 90% of the kiln workers being seasonal laborers. This seasonal nature diminishes the bargaining power of workers, who often feel compelled to return to the same job year after year because they become dependent on advance payment during the off-season.

The difficult nature of brick work in Bangladesh has impacts beyond its adult workforce. Children of kiln workers migrate seasonally with their parents. They lack access to quality education and sometimes are drawn into working in the kilns as child labor due to inadequate law enforcement (ILO, 2014)1/.

An environment and health survey financed by SEJLS reveals that working conditions in the brick kilns are abject. Sanitation is generally poor, and heat becomes intolerable during summer. The predominant mode of brick manufacturing – fired clay brickmaking (FCB) – emits harmful levels of pollution from fine particulates that can damage the respiratory system of kiln workers, 40% of whom reported cough, phlegm, and asthma. The strenuous movements to produce bricks, coupled with prolonged awkward postures, is a known cause of the musculoskeletal stress and injuries experienced by many kiln workers.

Greener technologies, better jobs

The BEST project is tackling these problems by introducing non-fired brickmaking (NFB), an alternative brick production method that curbs pollution and can be carried out year-round. Aligned with the government’s target of using 100% block instead of fired bricks in construction work, the new technology is good for the planet as its GHG emission reduction is estimated to be as much as 80%. The technology is also good for people. The jobs monitoring and evaluation system financed by SEJLS shows that the BEST project expects to help create 7,000 jobs. These clean jobs will have lower health risks and better pay, promising to improve the livelihoods of vulnerable populations working in the brick sector.

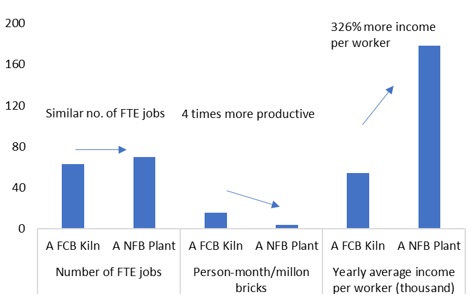

Figure 1: Estimated employment, productivity, and income for an FCB kiln and an NFB plant

Source: Study to address Key Jobs Challenges in the Brick Industry to move from “dirty and unsafe jobs” to “clean and safe jobs”, Vol III: Jobs and earnings.

Clean jobs carry lower occupational health and safety risks. Adopting non-fired brickmaking technology introduces highly mechanized processes for raw materials, intermediate, and final product handling. This mechanization eliminates physically taxing tasks and decreases physical strain on workers. Further, non-fired brickmaking technology removes the need for coal pulverization and loading, minimizing the risks of burns, scalding, and dust inhalation. The new approach also means an absence of hot, dusty, and hazardous work environments common in traditional kilns.

Clean jobs raise productivity and incomes. With the new technologies, seasonal brick laborers can transition into full-time positions protected by labor laws and entitled to employer-provided bonuses. Additionally, non-fired brickmaking plants are projected to yield about four times the productivity per worker compared to the old kilns (Figure 1). This shift could potentially triple average incomes for brick workers over a year post-technology transformation. The transition is nevertheless easy. Therefore, the BEST project has developed strategies supporting training for potential NFB plant workers, equipping them with in-demand skills essential to capitalize on the productivity gains using the new brick technologies.

The BEST project sheds light on the convergence of green technology and green jobs. SEJLS-supported studies have demonstrated how the project is helping transform a sector with more sustainable and better jobs – healthier, safer, more productive, and better-paying.

This is part of a series of blogs sharing insights from activities funded by SEJLS to support WBG operations in maximizing their impact on jobs.

1/ International Labour Office, (2014). Health hazards of child labour in brick kilns of Bangladesh.